What We Tested:

Contamination resistance of NHI Defender® Bearing Seals

Why We Tested:

Many of NHI’s customers use bearings in difficult applications that are subjected to hard environments. NHI has developed a special triple lip bearing seal to keep grease in and debris out, thereby increasing bearing and overall application life.

How We Tested:

The NHI Bearing Slurry Tester is designed to replicate various applications in the most extreme conditions in a manner that allows for accelerated testing. Bearings are rotated at speeds representative of the application while submerged in a proprietary Slurry mixture designed to corrode, penetrate, and abrade the test articles. After completing the pre-determined testing time critical features of the bearings including weight, torque, and vibration (measured as sound) are compared to the pre-test values. A final analysis involves removal of the bearing seals for a visual inspection of the bearing for contaminates.

What We Found:

After 20 hours of continuous slurry testing the results were convincing.

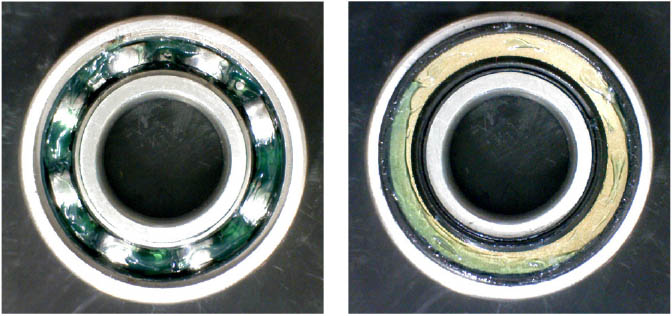

Competitor Bearing

measured a larger increase in weight and vibration indicating contaminates had penetrated the seal. This was validated via the visual inspection showing grease discoloration from the debris.

Bearing right

Inside of seal left

Bearing right

Inside of seal left

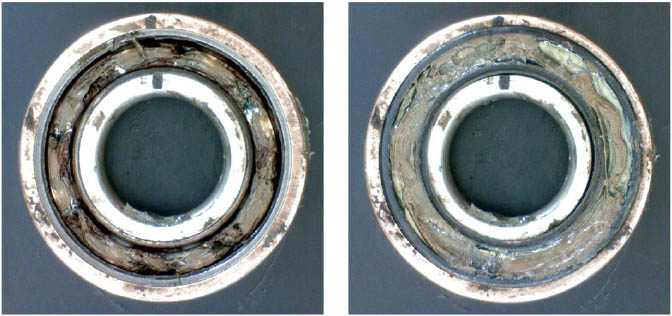

NHI Defender® bearings

measured minimal change in weight and vibration which was supported by the visual inspection which showed very slight indications of any contamination.

Bearing right

Inside of seal left

Bearing right

Inside of seal left

Conclusion:

NHI’s DEFENDER® BEARINGS stand tall above the competition at grease retention and contamination resistance.

Contact us today with your design, manufacturing or sourcing challenges.

Would you like to review your ideas with an NHI engineer?

Call 1.800.654.1090 or CONTACT us.